The medical device industry demands high precision, reliability, and innovation. Companies play an essential role in meeting these demands. They employ advanced technologies to ensure the production of high-quality medical devices. These innovations go beyond traditional molding techniques.

Medical injection molding companies enhance the quality and functionality of medical devices. They use cutting-edge technologies that ensure precision, efficiency, and safety. This article explores these advanced technologies to understand how they contribute to the medical device industry’s success.

Precision Engineering and High-Performance Molds

Micro-molding for Tiny Components

Micro-molding is a sophisticated technology used to produce tiny and detailed components. This technique is essential for manufacturing parts used in minimally invasive surgical instruments, microfluidic devices, and implantable devices. Micro-molding allows for the creation of components with features as small as a few micrometers, ensuring high precision and consistency.

High-Precision Molds

The development of high-precision molds is crucial for the production of these devices. These molds are crafted using advanced engineering techniques to achieve tight tolerances. High-precision molds ensure that each part produced meets exact specifications, minimizing the risk of defects and enhancing the overall reliability of medical devices. Implementing computer-aided design (CAD) and computer-aided manufacturing (CAM) in mold development notably enhances precision.

Advanced Materials and Coatings

Biocompatible Plastics

Biocompatible plastics are essential in medical device manufacturing. These materials are designed to be compatible with human tissues and fluids, reducing the risk of adverse reactions. Common biocompatible plastics include polyethylene (PE), polypropylene (PP), and polycarbonate (PC). These materials are chosen for their durability, flexibility, and ability to withstand sterilization.

Antimicrobial Coatings

Antimicrobial coatings are another significant advancement in injection molding. These coatings are applied to medical devices to inhibit the development of bacteria and other microorganisms. Antimicrobial coatings are particularly important for devices that come into direct contact with patients, like catheters and surgical instruments. They help reduce the risk of infections and enhance patient safety.

Automation and Smart Manufacturing

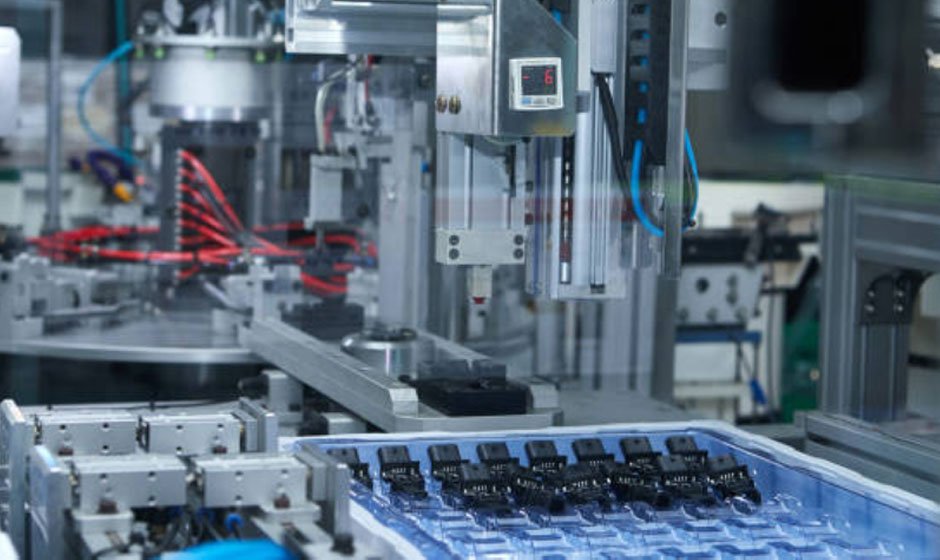

Automated Injection Molding Machines

Automation in injection molding machines has revolutionized the manufacturing process. This automation ensures consistent quality and reduces human error. Automated injection molding machines can produce large volumes of components quickly and efficiently, meeting the industry’s high demands.

Smart Manufacturing and IoT Integration

The integration of the Internet of Things (IoT) in manufacturing processes has led to the development of smart factories. In injection molding, IoT enables real-time monitoring and data collection. This technology allows for predictive maintenance, reducing downtime, and increasing productivity. Smart manufacturing also enhances traceability, ensuring that every component can be tracked throughout production, which is crucial for regulatory compliance.

Additive Manufacturing and Hybrid Techniques

3D Printing for Prototyping and Production

In some cases, 3D printing is also used for small-scale production of complex parts that are difficult to produce with traditional molding techniques. Combining 3D printing with injection molding can enhance the efficiency and flexibility of the manufacturing process.

Hybrid Manufacturing Techniques

Hybrid manufacturing techniques combine traditional injection molding with advanced technologies like 3D printing and laser sintering. These hybrid approaches enable the production of components with complex geometries and customized features. For example, a mold might be 3D printed with intricate internal structures, which is then used for injection molding to produce high-quality devices. Hybrid manufacturing offers the best of both worlds, leveraging the strengths of different technologies to achieve superior results.

Quality Control and Regulatory Compliance

Rigorous Testing and Inspection

Quality control is a cornerstone of medical device manufacturing. Advanced testing and inspection technologies ensure that each component meets stringent quality standards. Techniques such as automated optical inspection (AOI), coordinate measuring machines (CMM), and non-destructive testing (NDT) detect defects and verify dimensions. These methods help maintain high quality and reliability in these devices.

Compliance with Regulatory Standards

Medical injection molding companies must comply with various regulatory standards, such as those set by the FDA and ISO, and advanced technologies aid in achieving and maintaining compliance by ensuring consistent production quality and thorough documentation. Traceability systems track every component from raw material to finished product, providing a transparent and auditable manufacturing process. Compliance with regulatory standards ensures that these devices are safe, effective, and reliable.

Sustainability and Eco-Friendly Practices

Eco-Friendly Materials

Sustainability is an increasing focus in medical device manufacturing. Eco-friendly materials, such as biodegradable and recyclable plastics, are being developed and used in injection molding. These materials reduce the environmental impact of medical devices while maintaining high performance and safety standards.

Energy-Efficient Manufacturing

Modern injection molding machines are designed to consume less energy, reducing the manufacturing process’s carbon footprint. Energy-efficient practices benefit the environment and lower operational costs, making the production of medical devices more sustainable and economical.

Advanced technologies in medical injection molding are driving innovation and improving the quality and reliability of medical devices. These technologies ensure that medical devices meet the highest standards of safety and effectiveness, ultimately enhancing patient care and healthcare outcomes. As technology keeps evolving, the capabilities of medical injection molding will expand, further revolutionizing the healthcare industry.